Additive manufacturing is adding successive layers to build a three-dimensional object with a computer-driven output device. Many industries are using this technology to reduce production costs while increasing manufacturing quality and efficiency. Oqton’s Advanced Computer Vision AI technology offers cutting edge capabilities that can help improve additive manufacturing processes in various ways.

By automating the process of monitoring serial parts produced through additive manufacturing, Oqton’s AI allows manufacturers to reduce costs in terms of time and labour. In addition, it ensures that the manufactured parts meet required precision levels and reduces risk due to human error. Furthermore, Oqton’s AI technology can help identify flaws in printed parts and provide feedback so that corrective actions can be taken quickly. This feedback loop will improve results continuously, enhancing production quality and reducing waste costs. Finally, Oqton’s AI technology makes possible real-time fine-tuning adjustments that can optimise overall performance and provide predictive maintenance techniques for detecting potential failure points before they cause any damage or costly repairs.

In summary, manufacturers are set to benefit from improved productivity through cost savings on labour, enhanced accuracy through fewer errors, reduced waste output thanks to improved detection of flaws early on in the process, optimised printing performance via real-time adjustments in settings according to collected data points and more reliable preventive maintenance techniques due to predictive analytics feedback loops steered by intelligent algorithms powered by Oqton’s AI technology layer which sits atop traditional automation processes used within additive manufacturing markets.

What is Oqton?

Oqton is a startup that specialises in integrating Artificial Intelligence into additive manufacturing. They have recently secured $40 million in a round of funding from various investors to further develop their AI technology for additive manufacturing.

This section will explore the groundbreaking technology of Oqton and look into how their AI technology can benefit additive manufacturing.

Overview of Oqton’s AI technology

Oqton is an AI tool that provides solutions for the additive manufacturing industry. Using deep learning, machine learning and other advanced techniques, Oqton’s AI technology can simplify how people design and manufacture products. It achieves this by automatically analysing all relevant data concerning the design process and optimising the production process by leveraging this knowledge. With Oqton, companies can benefit from several features that can improve their product designs and production efficiency.

Oqton’s AI-based solutions can shorten development cycles while reducing production costs by automating certain aspects of the design process. Additionally, these solutions are capable of increasing overall flexibility in product design. With an intuitive interface and a powerful analytics engine, users can make quick decisions to reach their desired results with minimal effort. The result is unprecedented control over product designs so users can always achieve maximum quality in their finished parts.

Furthermore, Oqton’s analytics platform allows for insights into how different tools used within additive manufacturing affect part performance or build speed. By integrating these analyses with pricing data from suppliers worldwide, companies can reduce costs in real-time without compromising on quality or cost savings – resulting in a higher ROI than ever before. With access to up-to-date supplier prices and availability across a wide range of materials and processes, users are guaranteed never to settle for what they are given – ensuring they always have access to superior value no matter where they go!

Oqton raises $40 million to apply AI to additive manufacturing

Oqton has raised $40 million in a Series A round of funding to apply their AI technology to additive manufacturing. This investment is set to bring many benefits to this industry, such as improved speed, accuracy and efficiency in producing parts and components.

Let’s dive into the details of these benefits and how they will revolutionise additive manufacturing.

Automated design and simulation

Oqton’s Artificial Intelligence (AI) technology plays a major role in making the additive manufacturing process more efficient and reliable. Automated design and simulation are two core components of Oqton’s AI-powered solutions. Automated design analysis and optimises the existing designs according to key factors such as time, cost, and compliance.

On the other hand, AI-generated simulations can digitally predict the outcome of actual builds for reliability assessment. This helps manufacturers avoid having to go through a physical testing process for each iteration, allowing them to use their resources and time more effectively.

Moreover, Oqton’s solutions can automatically generate designs by suggesting possible combinations without having designers manually explore various options in a finite pool of materials, finishes, geometries or parameters. This enables companies to quickly reach the desired production capabilities without conducting extensive research or continuously determining whether a new part is feasible with their existing supplies.

In addition, AI-driven simulations provide valuable information about each build allowing designers and engineers to visualise potential issues before they occur–helping avoid costly production errors or delays down the line.

Enhanced process control

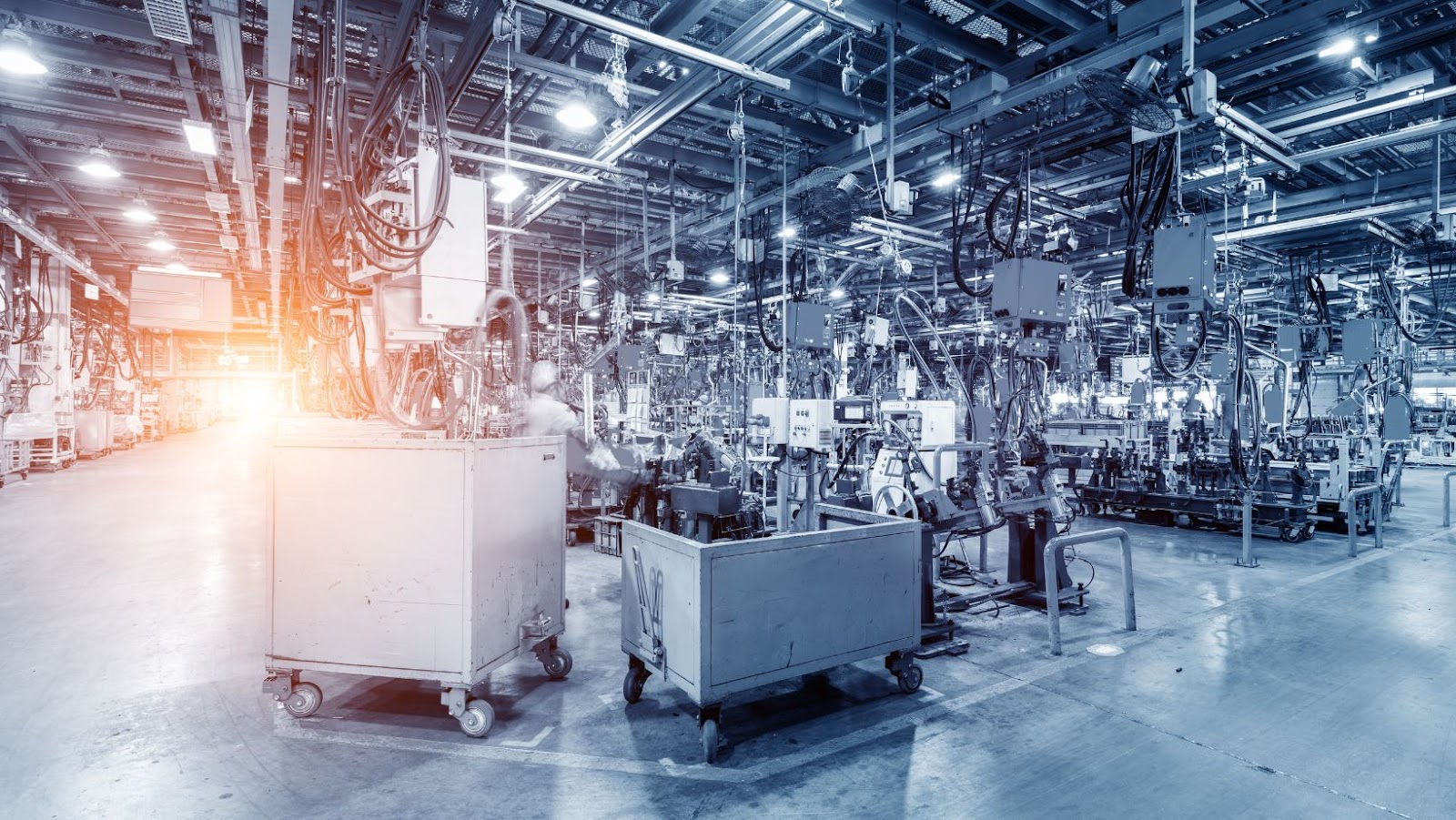

Oqton’s AI technology enables the dynamic control of a range of additive manufacturing processes. This means that operators can continuously and automatically monitor the progress of an additive manufacturing process and make adjustments in response to changes in parameters such as build orientation, speed, and material type.

With Oqton’s AI technology, manufacturers can quickly adapt their processes to changing conditions within their production environment without manual intervention. This increases efficiency and reduces downtime due to machine maintenance or adjustments.

In addition, Oqton’s AI technology also optimises material usage by detecting potential flaws and waste pre-production phase so that material isn’t used unnecessarily during the production process. As a result, additive manufacturing productivity is improved while costs are minimised.

Reduced costs and waste

Oqton’s artificial intelligence (AI) technology can significantly reduce the cost and waste of additive manufacturing, resulting in a more efficient and economical manufacturing process.

By leveraging AI computer vision, Oqton’s software automates the quality and material-checking process for each layer of the additive build. This helps to speed up production, improve product quality, and identify any issues before they lead to costly mistakes or delays in manufacturing. Additionally, Oqton’s automated processes save time by reducing human error, improving consistency across all parts made with their machines. Through these efficiencies, Oqton’s AI technology helps additive manufacturers save on expensive production costs that can be wasted due to faulty prints or misalignments caused by manual inspection errors.

The use of AI has also enabled the implementation of continuous feedback loops during the printing process. Thanks to adaptive learning algorithms, this technology has identified defects immediately, allowing for almost instant corrective action that can save costly reprints. Furthermore, its predictive capabilities help manufacturers adjust their builds to avoid future problems while monitoring quality assurance on an ongoing basis.

Combining AI computer vision with automated processes to reduce waste from failed prints and faulty parts inspection errors, Oqton’s AI technology offers additive manufacturers a cost-effective means of achieving a more efficient production process with improved quality control measures.

Oqton’s $40 million funding

Oqton, a Netherlands-based startup, recently announced a $40 million funding round to apply AI to additive manufacturing. This is a major step towards revolutionising the additive manufacturing industry and will take it to the next level.

Let us look closer at Oqton’s AI technology and how it can benefit additive manufacturing.

Overview of the funding round

Oqton, the leading provider of AI-driven software solutions for the additive manufacturing industry, has announced its latest round of funding totaling $40 million, led by Construct Capital and Steelhead Ventures. This is the first time a venture-backed software platform specifically targeting the industrial additive manufacturing market has obtained funding of this magnitude.

The investment will further accelerate Oqton’s mission to automate and scale industrial front-end workflows, enabling smarter computational manufacturing operations — from resource optimization to quality assurance — to deliver made-to-order parts faster. Oqton combines unique capabilities like advanced machine learning models, edge computing and deep domain knowledge, and comprehensive platform flexibility , allowing it to offer a comprehensive suite of industrial additive manufacturing solutions in OEM and standalone formats.

This funding represents a major milestone for Oqton’s vision for bringing artificial intelligence-enabled applications into 3D printing workflows with an accent on simplifying and streamlining programming activities — from quoting parameter accuracy through part optimization and post-sintered residual stress minimization which are key advantages amongst industry players looking for superior flexibility regarding printed parts traceability, allowing real cost Savings in additive processes as well as other areas throughout digital production process pipelines.

How the funding will be used

A $40 million Series B investment into Oqton, an AI-powered Software-as-a-Service (SaaS) platform for additive manufacturing and metal fabrication, is set to fuel the advancement of their innovative technology. The funding round was led by Tribe Capital and Intel Capital with participation from existing investors Audi Electronics Venture, Hello Tomorrow, and Henkel. This brings Oqton’s total equity investments to over $50 million.

The company plans to use the new capital to build out its development team and provide global expansion for the platform. In addition, it will further develop the cloud-based control system that optimises Additive Manufacturing (AM) processes and offers unprecedented flexibility in production operations including 3D printing, machining, cutting, welding and finishing technologies. The intuitive interface of this system simplifies operations required for creating complex parts with many different production mechanics while achieving unprecedented performance levels in terms of cost reduction, lead time reduction and recyclability optimization.

In addition to automation features that improve part quality consistency, Oqton has launched a library of automated process parameters backed by machine learning algorithms so AM processes can be completed faster and with fewer errors compared to manual setup methods.

tags = Oqton, raises $40 million, apply AI to additive manufacturing, engineering software, manufacturing hardware, oqton os cnc 3d 40m serieswiggersventurebeat, startup developing a factory operating system, robotic welding, and CNC machining